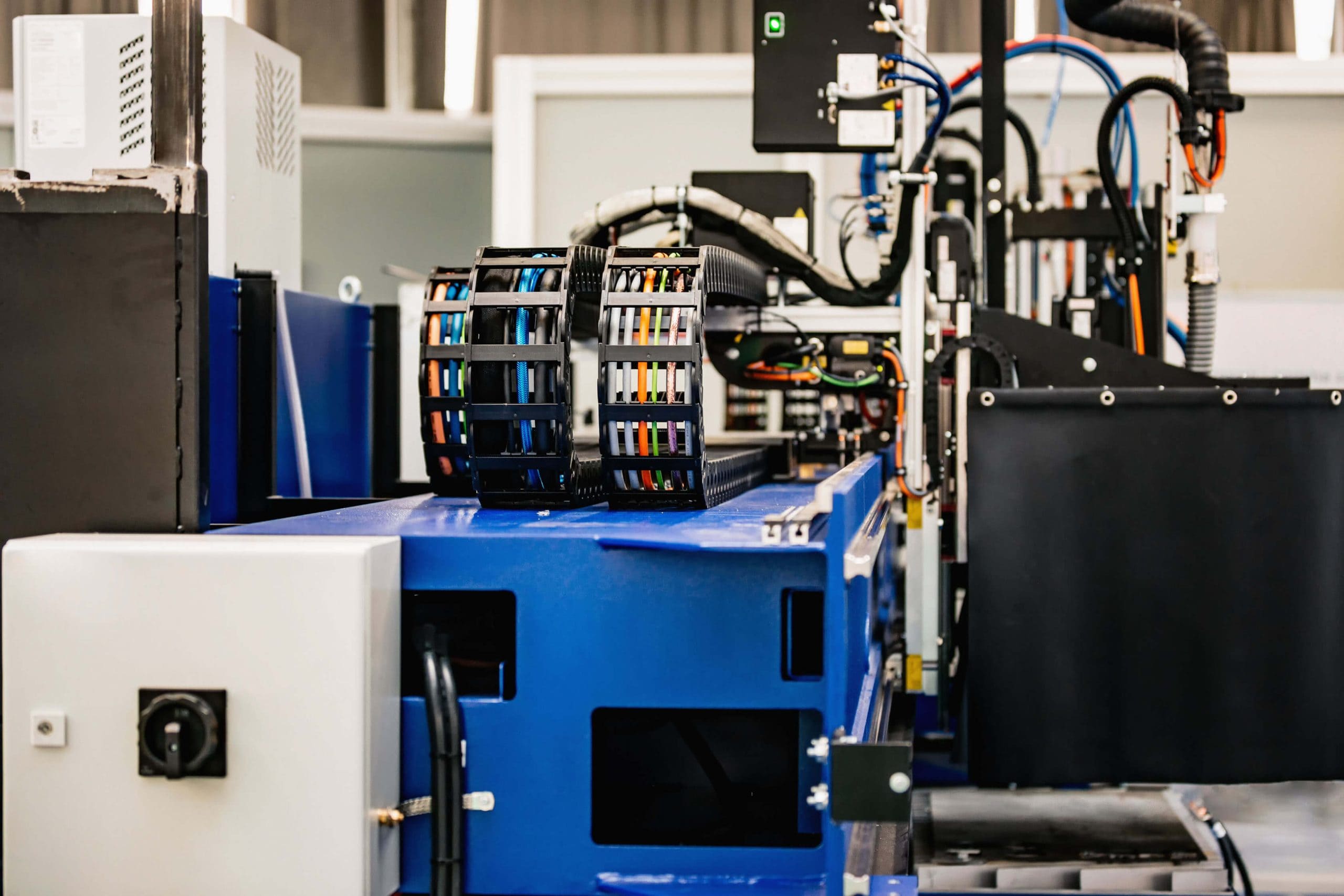

Machine Condition Monitoring Techniques

What Is Condition Monitoring?

Hands-on condition monitoring is essential for maximum bearing service life and machine health.

To help ensure long bearing service life, it is important to determine the condition of machinery and bearings while in operation.

Good predictive maintenance will help reduce machine downtime and decrease overall maintenance costs.

What is the Purpose of Condition Monitoring?

Condition monitoring is a key component of managing the maintenance and operability activities in a modern operating and maintenance organization for nuclear and sophisticated power plants.

In essence, condition monitoring aids in maintaining the efficiency and safety of plant operations.

The corresponding decision contexts are represented as process models in order to create a framework for comprehending issues and solutions linked to the use of condition monitoring data in strategic and operational maintenance decision-making.

Machine Health Condition Monitoring Techniques With SKF

The following condition-monitoring products are essential monitoring tools that no industrial manufacturing plant should be without.

Temperature Monitoring

Thermometers

Thermometers are essential for accurate temperature measurement of general equipment.

Since the dawn of the industrial age, operators and technicians have known that abnormal temperatures often indicate that something is wrong with the machine.

Thermometers can help find and then measure these hotspots, allowing for further analysis.

SKF has a variety of thermometers and thermocouple probes to complement your condition monitoring or predictive maintenance program by assessing and reporting on temperature.

- General-purpose thermometers

- Contact thermometers

- Infrared thermometers

- Contact and infrared thermometers

- Dual laser infrared and contact thermometers

- K-type thermocouple probes

Thermal camera

A thermal camera enables you to detect hot spots before they cause trouble

Using an SKF thermal camera is a proactive way to help you detect problems before they occur, increasing uptime and improving safety.

They allow you to be able to visualize potential problems, invisible to the naked eye, by presenting a picture of the heat distribution of an asset.

The thermal image, presented on a large LCD screen, shows you where the temperature is either too hot or too cold, allowing you to pinpoint potential problems quickly.

- Thermal camera TKTI 21

- Thermal camera TKTI 31

Speed Monitoring

Digital tachometer

Pinpoint accuracy combined with measurement versatility

The SKF TKRT 10 is a fast and accurate tachometer utilizing a laser or contact to measure rotational and linear speeds.

Equipped with a laser and a range of contact adapters, it is a versatile instrument and suits many different applications

- Wide speed measurement range: up to 99 999 r/min for laser measurement and 20 000 r/min using contact adapters

- Measurement modes include rotational speed, total revolutions, frequency, surface speed, and length in both metric and imperial units

- A laser can be used for safe and quick, non-contact rotational speed measurements at distances up to 0.5 m (20 in.)

- A large back-lit LCD enables easy reading in almost all light conditions

- The angular range of ±45° to target helps facilitate easy measuring

- Up to 10 readings can be stored for later reference

- Compact design; one-hand operated instrument

- Supplied in carrying case for protection and portability

Multi-functional digital tachometer

The multi-functional digital tachometer TKRT 20 is a user–friendly and accurate digital tachometer utilizing laser or contact for measuring rotational and linear speed.

Equipped with a laser and contact adaptor, it offers excellent speed measurement versatility in five different modes.

- With this digital tachometer, the user can select to measure: rpm, rps, m, ft, or yards per minute or second. length, revolution counting, or time interval

- The wide speed range and the various measurement modes make the TKRT 20 suitable for measuring speed in many applications

- A large angular range of ± 80° to target facilitates easy measuring in areas where straight-line access is difficult

- The large inverting LCD facilitates easy reading even when pointing the unit down into the machinery

- Compact design; one-hand operated instrument

- Supplied in carrying case for protection and portability

- The digital tachometer TKRT 20 can also be equipped with a remote laser sensor, which is optionally available.

Visual

Endoscopes

Fast and easy inspection with video function

SKF Endoscopes TKES 10 series are first-line inspection tools that can be used for the internal inspection of machinery. They help minimize the need to disassemble machinery for inspection, saving time and money.

The compact display unit, with a 3.5” backlit screen, allows images and video to be saved and recalled, or to be downloaded and shared with others.

Three different models cater to most needs and are equipped with powerful variable LED lighting, allowing inspections in dark locations.

- A high-resolution miniature camera with up to 2™ digital zoom gives a clear and sharp full-screen image.

- Available with a 1-meter (3.3 ft) insertion tube in three different variants: flexible, semi-rigid, or with an articulating tip.

- A small tip diameter of 5,8 mm (0.23 in.), with a wide field of view, allows easy access to most applications.

- Supplied with a side view adapter allowing inspection of applications such as pipe walls.

- Powerful magnets and a tripod mount on the back of the display unit allow the display unit to be used “hands-free.”.

- Up to 50,000 photos or 120 minutes of video can be stored on the SD memory card supplied.

- Longer flexible and semi-rigid insertion tubes are available as accessories.

- Supplied in a sturdy carrying case complete with all necessary cables, universal mains charger, and cleaning kit.

Sound

Stethoscopes

Easily pinpoints bearing and machine noise

The SKF Electronic Stethoscope TMST 3 is a high-quality, sensitive instrument that enables the determination of troublesome machine parts by the detection of machine noises or vibrations.

TMST 3 includes a headset, two different length probes (70 and 220 mm), and a pre-recorded audio CD demonstrating the most commonly encountered troublesome machine noise, all supplied completely in a sturdy carrying case.

- Excellent sound quality helps to reliably identify the possible cause of the noise

- User-friendly and easy to operate; no special training is required

- The lightweight ergonomic design makes it easy to operate with one hand

- Excellent quality headset for optimum sound quality even in very high-noise environments

- Pre-recorded demonstration CDs and output for analogue recording help facilitate analysis and comparison

- Supplied with two probes, 70 and 220 mm (2,8 and 8,7 in), enabling reach almost anywhere

- Adjustable digital volume control up to 32 levels to reach the desired volume.

Ultrasonic leak detector

Quick and easy detection of air leaks

Any compressed air system can experience leaks, which amplify the load on compressors and increase costs.

The TKSU 10 helps users easily find leaks from a distance, even in noisy industrial environments, via its ultrasound measurement sensor.

The built-in LED display assists the user in adjusting sensitivity and shows the measured ultrasound noise from leaking air, allowing the quantification of leaks and prioritization of repairs.

The TKSU 10 is designed for use in all industries utilizing compressed air, and it is particularly recommended for paper and chemical industries, as well as workshops with air-driven power tools.

- Easy to use; no training required

- Leak detection from a distance in noisy industrial environments

- The Colour LED display assists in adjusting sensitivity settings and shows measurement values

- Reduces energy and maintenance costs via leak identification and repair

- Lightweight, handheld device with industrial headset included

- Independently adjustable sensor sensitivity and headset volume

- A flexible probe helps find leaks in difficult-to-access locations

- The headset features a neckband design to wear with a protective helmet

Vibration

Basic handheld vibration sensor

Now both novice users and experts can easily, quickly, and accurately check the condition of rotating equipment throughout your facility.

Equipping your maintenance and operations personnel with this rugged, ergonomic, and easy-to-use instrument can provide early warning of potential machine problems before a costly failure occurs.

Features

- Quick and easy to set up and use, measurements are shown on a bright display viewable in low light to direct sunlight. Free online training is also available.

- Lightweight, compact, and ergonomically designed, the SKF Machine Condition Advisor fits neatly at the belt line, in a pocket, or in a tool kit. Exceptionally durable, the unit is rated IP 54 for use in industrial environments.

- Alert and Danger prompts provide increased diagnostic confidence.

- Measuring velocity, enveloped acceleration, and temperature simultaneously save time.

- Efficient, economical, and environmentally friendly, the rechargeable SKF Machine Condition Advisor operates for 10 hours on a single charge.

- Flexible enough to work with standard 100 mV/g constant current accelerometers, an optional external sensor can be used for hard-to-reach locations and more repeatable and accurate measurement results.

Multiple measurements with a single device

The SKF Machine Condition Advisor provides an overall “velocity” vibration reading that measures vibration signals from the machine and automatically compares them to pre-programmed International Organization for Standardization (ISO) guidelines.

An “Alert” or “Danger” alarm displays when measurements exceed those guidelines. Simultaneously an “enveloped acceleration” measurement is taken and compared to established bearing vibration guidelines to verify conformity or indicate potential bearing damage.

The SKF Machine Condition Advisor also measures temperature using an infrared sensor to indicate uncharacteristic heat.

Accuracy, flexibility, and confidence

When performing measurements, the SKF Machine Condition Advisor’s acceleration sensor input signal is processed to produce two different measurements for each POINT on the machinery – overall velocity and enveloped acceleration.

At the same time, the SKF Machine Condition Advisor’s non-contact infrared sensor measures the surface temperature of the measurement location and simultaneously displays all three measurement values.

Depending on the SKF Machine Condition Advisor’s System setting, the front-panel LCD simultaneously displays:

- Metric or Imperial units

- Velocity in mm/s RMS or in./s derived Peak

- The temperature in Celsius or Fahrenheit

- Acceleration enveloping readings in gE

Quick Collect Sensor

The SKF QuickCollect sensor is an easy-to-use Bluetooth-enabled handheld sensor that connects to apps that work with both iOS and Android tablets and smartphones (and iOS smartwatches).

Combining vibration and temperature sensing, overall data can be viewed on the spot in real time or pushed to the cloud for future analysis.

This SKF QuickCollect sensor is ideal for service, reliability, operations, or maintenance personnel as part of a walk-around data collection program.

Features

- Velocity, acceleration enveloping, and temperature measurements

- Bluetooth communication with tablets, smartphones, smartwatches

- Easy-to-use sensors and apps

- Easy to understand indications of machine condition

- Rugged industrial design – Drop test 1,8 m (6 ft.), water and dust resistant (IP65)

- Suitable for use in hazardous environments (ATEX Zone 1, Class 1, Div 1) (pending)

- Rechargeable lithium battery (8 hours normal usage)

- Option to connect, store, and share data on the Cloud

- Option to connect directly to SKF Remote Diagnostic Services

- Connects to apps that work with both iOS and Android tablets and smartphones (and iOS smartwatches).

Benefits

- Gets you started quickly

- Can be used with minimum training and experience

- Identify developing rotating machinery issues before they become problems

- Connect directly to expert advice when you need it

- Expand functionality via apps to grow and complement your existing maintenance program

Measurements taken by the sensor are shown on your mobile device, which displays velocity, acceleration, and temperature as shown below.

Each reading displays a current overall measurement, including alarm status, minimum and maximum values, and alert and danger thresholds.

Static vibration sensor

The SKF Machine Condition Indicator is an economical vibration sensor and indicator for monitoring non-critical machines. It is ideal for machinery with constant operating conditions not previously monitored in plants.

The device can be compared to the “check engine” light in a car. What the “check engine” light does for the car, the SKF Machine Condition Indicator does for industrial machinery.

Internal sensors measure velocity, enveloped acceleration (bearing or gear impulsive vibration), and machine surface temperature.

The included magnetic read key is used to activate the SKF Machine Condition Indicator, change operating modes, set vibration baselines, and acknowledge alarms.

The unit features three LEDs to indicate the machine and bearing condition. Once the unit is illuminated, it alerts the predictive maintenance technician to do a root cause analysis on the machine.

In addition, it features a barcode with a serial number for machine identification purposes and easy incorporation into an Operator Driven Reliability (ODR) program, maintenance routes, or scheduled check-ups.

Electrical discharge detector

Detect electrical discharges in electric motor bearings

The SKF Electrical Discharge Detector Pen (EDD Pen) is a simple-to-use hand-held instrument for detecting electrical discharges in electric motor bearings.

Electrical discharges are a result of motor shaft voltages discharging to earth through the bearing, causing electrical erosion, lubricant degradation and ultimately bearing failure.

Electric motors are more vulnerable to suffering electrical erosion in bearings when controlled by a Variable Frequency Drive.

When incorporated into a predictive maintenance programme, the EDD Pen can help detect bearings more susceptible to failure and significantly prevent unplanned machine downtime.

- A unique remote solution allows operation at a distance from the motors. This helps protect the user from touching machinery in motion

- SKF technology

- No special training required

- Capable of detecting electrical discharges on a time base of 10 seconds, 30 seconds, or indefinite

- LED Backlit screen, allows use in dark environments

- IP 55 can be used in most industrial environments

- Supplied standard with batteries, a spare antenna, and language-free Instructions for use in a carrying case

To help you achieve this goal, SKF has developed a wide range of instruments for analyzing the critical environmental conditions that have an impact on bearing and machine performance.

Greenpeg as an authorized SKF distributor and SKF partner in Nigeria is positioned to support you with SKF products and SKF condition monitoring services to reduce downtime and extend the lifetime of your equipment.